| Place of Origin: | ShenZhen China |

|---|---|

| Brand Name: | Kingsum ElectronicPCB |

| Certification: | IATF16949-2016 | ISO9001 2015 | UL 337072 | ROHS |

| Model Number: | L-PCB-Kingsum Electronic01 |

| Minimum Order Quantity: | 1pc |

|---|---|

| Price: | case by case |

| Packaging Details: | Vacuum bag |

| Delivery Time: | 5-8days |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 100000pcs/month |

| PCB Material: | Aluminum | Spec: | As Per Customer Gerber Files |

|---|---|---|---|

| Bom List: | As Per Customer Bom List For Components | Board Thickness: | 0.8-2.0mm |

| High Light: | led printed circuit board,led light circuit board | ||

1. Detailed Specifications

| Material | FR4 |

| Board Thickness | 1.6mm |

| Surface Treatment | Lead Free |

| Copper Thickness | 1/1/1/1/1/1OZ |

| Soldermask | Black |

| Silkscreen | White |

| The Min Laser Drill Hole | 4 Mill |

| Panel | V-Cut |

Introduction:

Printed Circuit Board Assembly it to plug the SMT(Surface Mounted Technolofy) and the DIP in the Printed Circuit Board, also called PCBA.

Production:

Both SMT and DIP are means of integrating components in the PCB board. The main difference is that SMT does not need to drill holes on the PCB,while it's nacessary for the DIP to plug the pin of the component into the drilled hole.

SMT:

Mainly use the paste to pack machine to attach some micro components the PCB board. The production process is as follows: the PCB board positioning, solder paste printing, paste and pack, return to the soldering stove, finally inspection.

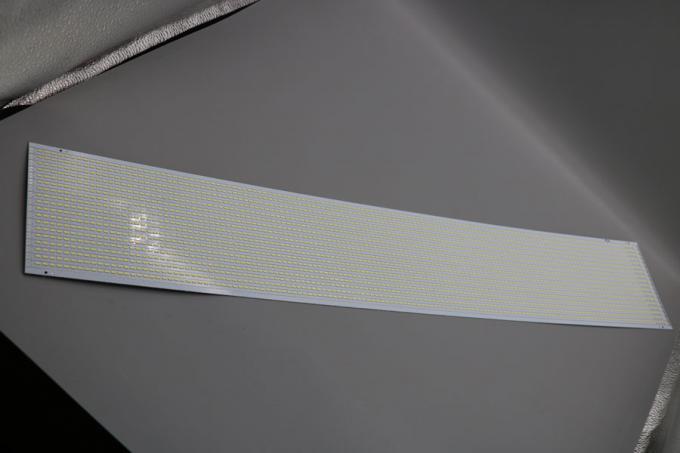

2. Pictures